Preventive Maintenance

Preventive maintenance on industrial can sealers

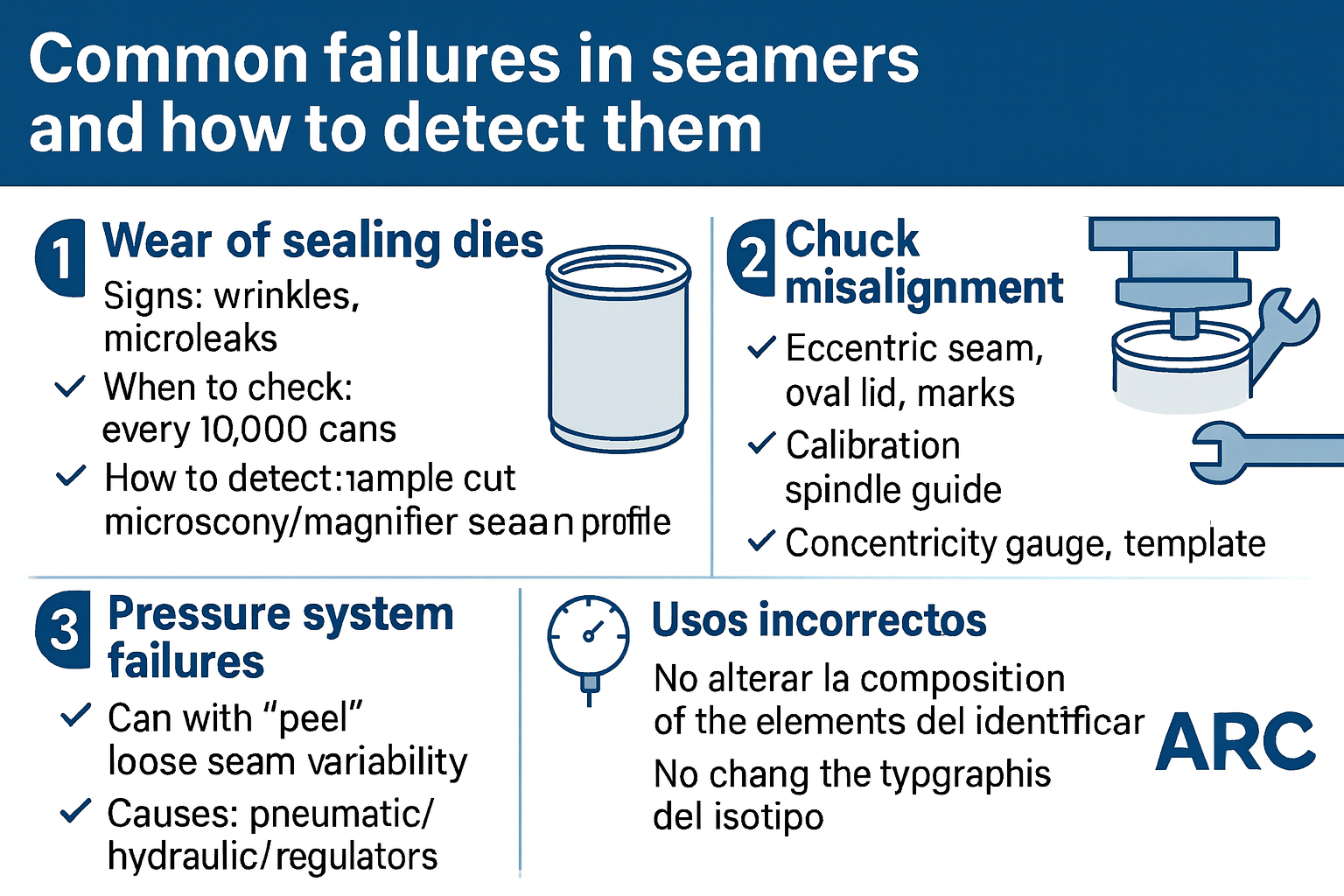

He preventive maintenance of sealers is crucial to ensure sealing quality and avoid production downtime. Our specialized technicians recommend inspections every 500 hours of operation.

The critical components such as sealing dies, chucks and heads require periodic adjustments to maintain tight sealing accuracy.

Key maintenance points:

- Inspection and adjustment of sealing dies

- Closing pressure calibration

- Vacuum system verification

- Lubrication of mechanical elements

- Sealing quality control

In ARC Distribution We offer customized maintenance contracts. Contact +34 673 779 909 for more information.