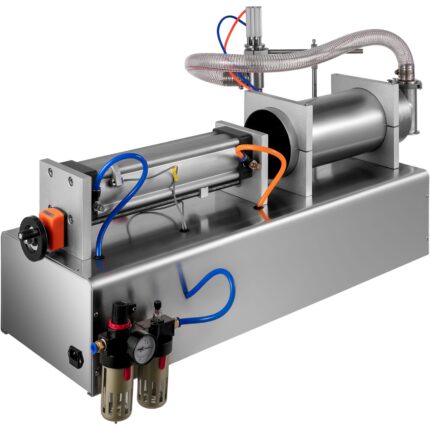

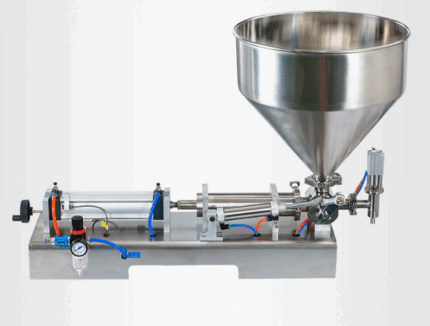

Piston fillers

Bottling machine for water, liquids, bleach, reagents, juice 1000-5000ml

Original price was: 3.206,25$.2.981,25$Current price is: 2.981,25$. Taxes includedBottling machine for viscous liquids, oil, detergent, 500 to 5000ml

Original price was: 3.318,75$.3.206,25$Current price is: 3.206,25$. Taxes includedDosing, bottling, with mixer and double filler 100 ml - 1000 ml

Original price was: 3.206,25$.2.812,50$Current price is: 2.812,50$. Taxes includedDosing, Bottling, Filling and Packaging Machine 100 ml - 1000 ml

Original price was: 2.362,50$.2.025,00$Current price is: 2.025,00$. Taxes includedPneumatic dosing and bottling machine for dense and viscous products 50 ml

Dosing machines, Viscous dosing machines, liquid fillers, bottle fillers, Filling Machines, Fillers for dense and viscous liquids, gravity liquid fillers, Piston fillers, Chemical industry machines

Original price was: 506,25$.483,75$Current price is: 483,75$. Taxes included

Piston Fillers: Precision for Liquid, Viscous, and Foamy Products

The piston fillers They are the ideal solution for product packaging viscous, foamy or chunky such as sauces, creams, purees, gels, jams, honey, detergents or liquid soaps. This type of machine is highly valued in sectors such as food, cosmetic, chemical and pharmaceutical, due to its robustness and ability to dose with extreme precision even difficult-to-handle products.

🔧 How it works:

The piston retracts to draw in a precise amount of product from the reservoir and then pressurizes it into the container. This mechanical process allows for complete volume control and prevents variations, air bubbles, or excessive dripping.

✅ Advantages of Piston Fillers

-

High filling precision, even with dense or particulate products.

-

Versatility: They fill from small doses to large formats by adjusting the cylinder.

-

Compatible with hot or cold products, depending on the material of the system.

-

Ideal for foaming liquids, since the system prevents aeration.

-

Easy cleaning and sanitizing, with versions in food grade stainless steel.

These machines are available in semi-automatic or fully automatic format, and can be integrated with conveyor belts, labelers and closers to form a complete packaging line.

🚫 Limitations to keep in mind

-

Not recommended for extremely fluid or volatile liquids.

-

It requires more maintenance than a gravity filler due to the moving parts.

-

For certain products with large solids, you may need special valves or heated hoppers.

🏭 Common applications

-

Food industry: chunky sauces, honey, yogurts, jams, purees.

-

Cosmetics: facial creams, body gels, thick shampoos.

-

Chemical industry: detergents, cleaning products, lubricants.

-

Pharmacy and supplements: gels, foaming syrups, oily solutions.