Back to products

Empty hard gelatin capsules vegetables sizes

22,63$ Taxes included

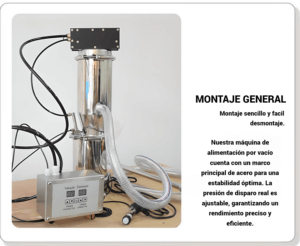

DUST SUCTION AND TRANSPORT MACHINE – HIGH EFFICIENCY AND PRECISION

2.616,05$ Taxes included

SKU:

AR00751

Category: Industrial Dust Suction and Transport Systems

Description

Available Models and Specifications

Powder Handling Equipment: Model QARVC1

Feeding Capacity: 500 kilos/hour

Air Consumption: 270 Liters/min

Air Pressure Supplied: 0.4-0.6 Megapascal (Mpa)

Overall Size: φ159×580 mm

Weight: 15 kilos

Recommended Uses:

The QARVC1 model is ideal for small production lines in the food and pharmaceutical industries. Perfect for suctioning and transporting powdered ingredients such as spices, sugar and medicines in small doses, ensuring precise and continuous feeding.

Powder Feeder for Machinery: Model QARVC2

Feeding Capacity: 700 kilos/hour

Air Consumption: 360 Liters/minute

Air Pressure Supplied: 0.4-0.6 Megapascal (Mpa)

Overall Size: φ213×720 mm

Weight: 21 kilos

Recommended Uses:

The QARVC2 model is suitable for medium-sized chemical and food industries. This powder feeder is excellent for handling larger volumes and is ideal for production processes that require a constant flow of materials such as flour and pigments.

Pneumatic Powder Conveyor: Model QARVC3

Feeding Capacity: 1500 kilos/hour

Air Consumption: 720 Liters/minute

Air Pressure Supplied: 0.4-0.6 Megapascal (Mpa)

Overall Size: φ290×850 mm

Weight: 30 kilos

Recommended Uses:

The QARVC3 model is optimal for large production lines in pharmaceutical and chemical industries. It handles large quantities of powder efficiently, ensuring constant and accurate feeding to production machines.

Industrial Dust Management Solutions: Model QARVC4

Feeding Capacity: 3000 kilos/hour

Air Consumption: 1440 Liters/minute

Air Pressure Supplied: 0.4-0.6 Megapascal (Mpa)

Overall Size: φ420×1150 mm

Weight: 40 kilos

Recommended Uses:

The QARVC4 model is perfect for large industrial facilities handling powdered products in high volumes. It is particularly suitable for the food and chemical industry, where high feeding capacity is essential to maintain efficiency.

Powder Feed System: Model QARVC5

Feeding Capacity: 6000 kilos/hour

Air Consumption: 2880 Liters/minute

Air Pressure Supplied: 0.4-0.6 Megapascal (Mpa)

Overall Size: φ420×1150 mm

Weight: 55 kilos

Recommended Uses:

Designed for large-scale production plants, the QVC5 model handles large quantities of powder efficiently. It is ideal for chemical and pharmaceutical industries that require fast and precise material transport.

Designed for large-scale production plants, the QVC5 model handles large quantities of powder efficiently. It is ideal for chemical and pharmaceutical industries that require fast and precise material transport.

Powder Conveying Machine: Model QARVC6

Feeding Capacity: 9000 kilos/hour

Air Consumption: 4320 Liters/minutes

Air Pressure Supplied: 0.4-0.6 Megapascal (Mpa)

Overall Size: φ420×1350 mm

Weight: 70 kilos

Recommended Uses:

The QVC6 model is the most robust and is ideal for the most demanding industrial operations. Suitable for factories that require the transport of large volumes of powder quickly and efficiently, especially in the chemical and manufacturing industry.

Benefits and Industrial Applications

Benefits of Dust Suction and Transport Machines:

- High Efficiency: Continuous and uninterrupted transport.

- Versatility: Compatible with various types of powders and particles.

- Precision: Constant and controlled feeding, improving process efficiency.

- Durability: Built with durable materials, ensuring a long service life.

- Easy to Use: Intuitive system and easy maintenance.

Industrial Applications:

- Food Industry: Transport of powdered ingredients such as flour, sugar, and spices.

- Pharmaceutical Industry: Handling of medicinal powders and dietary supplements.

- Chemical industry: Transport of powdered chemicals, pigments and resins.

- Manufacture: Powder feeding in production and packaging processes.

At ARC Distribution, we take our products to all continents:

- North America

- South America

- Europe

- Africa

- Asia

- Oceania

Local Distribution Companies

- Spain: We operate throughout Europe with fast and efficient deliveries.

- Colombia: We serve all of South America with quality service and fast deliveries.

- USA: Comprehensive coverage throughout North America, including Miami.

Request more information

In ARC distribution We advise you on the optimization of the factory or the creation of a new industry

Reviews (0)

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.