Thermal Induction Sealing Machine for sealing lids

294,65$ Taxes included

Electric deep fryer for fried fish, potatoes, etc. 2x10L ?

212,15$ Taxes included

Semi-automatic thermal induction sealing machine for sealing lids

2.333,63$ Taxes included

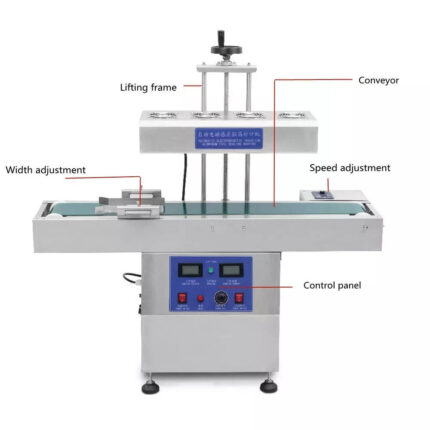

semi-automatic thermal induction sealing machine

Induction heat sealing improves product quality, prevents absorption of natural moisture, extends shelf life, and adds security against counterfeiting.

Semi-automatic induction sealer recommended for high production, economical, with sealing head for container mouth diameters from

Ø20 mm to Ø80 mm.

It is characterized by being compact and lightweight, but at the same time it has the power and effectiveness necessary for the vast majority of induction sealing applications; controlled by a highly efficient and low power consumption SIEMENS “IGBT” chip. Our recommendation, Quality-Price for high productions.

SKU:

AR00273

Categories: Induction sealers, cappers

Description

This thermal induction sealing machine works on non-metallic bottles, which must be plastic or glass, as well as cup-shaped containers. It is an upgrade for the popular airtight sealing method. Thermal induction sealing improves product quality, prevents natural moisture absorption, prolongs shelf life, adds security against counterfeiting. Nowadays, sealing installation has become essential and is widely used in the chemical, pharmaceutical, cosmetic, beverage and food industries, among others.

- Suitable for glass or plastic bottles, such as ABS, PE (HDPE, LDPE), PET, PP, PS, PVC, (Do not use metal containers) screw caps, tamper evident caps, etc.

- It works to seal a wide variety of packaged products such as: powders, capsules and pills, milk, water, juice, yogurt, alcohol, gelatin, processed foods, motor oil, etc.

- semiautomatic.

- Hermetic sealing by heat induction without direct contact.

- It is very easy to handle since it is designed with a panel.

- No moving parts, no noise, the electronic components mounted are 100% solid state for long life.

- It is very safe to use, it has a protection circuit against current overloads and overheating.

- High quality and Safety Standard: GB 15579 and 1995

- Power: 110V and 220V

- Output power: 1800W

- Sealing diameter from: 20 to 80 mm

- Working ambient temperature: 25 to 45 °C

- Relative Humidity: ≤ 95%

- Adjustable height: 20 to 350mm.

- Belt speed: up to 8.5m/min.

What is induction packaging sealing?

Induction container sealers are based on a clean, contactless container sealing system through which an aluminium lid or 'disc' is glued to the perimeter of the mouth of a container.

First of all, to seal a container by induction, it is essential to have a screw-on lid, and this cannot be metal. The induction disc/cap must already be placed inside the lid.

Regarding the body of the container, it is always recommended to use any plastic polymer (PP, PET, PE, etc.). For glass containers, we recommend using the conduction sealing system, also known as: thermo-sealing.

A cap suitable for induction sealing can be composed of the following elements (layers):

Internal "burr-free" plug, suitable for incorporation of aluminium disc / operculum

Cardboard: This element has a double function, since it is not only necessary to incorporate and center the seal on the cap, but it will also guarantee that the seal has adequate contact with the mouth of the container once the cap is closed and before induction sealing.

Adhesive layers

Aluminium foil/lid. Without a doubt, this is the most important element of all, as without it, it would be impossible to seal the container. Nowadays, there are different types of lids, the choice of which will depend on the type of product you want to seal.

Información adicional

| Weight | 50 kg |

|---|---|

| Dimensions | 60 × 60 × 50 cm |

Reviews (0)

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.