tablet forming machines, tablet compactors, industrial granulators

Here you will find all kinds of industrial tablet forming or compacting machines.

Tablet pressing machines, both in dry powder and with a touch of moisture

Industrial tableting and compacting machines

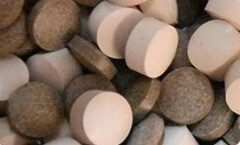

The tablet presses, Industrial tablet compactors and granulators They are key machines in the production of tablets, each adapted to the specific needs of the process. Presses and compactors compress powders under high pressure, ideal for materials that require intense compression, while granulators prepare uniform granules, improving dosage and quality of the tablets. When the tablets have a degree of humidity, specialized machinery is required to handle the wet content without compromising product quality, involving adjustments in temperature, pressure, and mold design. Correct selection and configuration of these machines ensures that the tablets meet precise specifications for size, shape, structural integrity, and effective release of active ingredients, which is crucial to the success of their production.

Industrial tablet forming machines

In our catalog you will find a wide selection of Industrial rotary machines for tablets pills, designed to cover all your production needs.

Moisture-Proof Tablet Compactor

In this section, you will discover machines specialized in compact tablets either tablets from moist and pasty products, specifically designed to handle these

Powder tablet pressing machine

Tablet forming machines

The tablet forming machines or tablet compactors They are widely used for compressing powder and turn them into tablets by applying pressure. The compactors They offer similar functionality, but are optimized to work with materials that require greater compression force from the 2 kilonewtons to the 100 kilo newtonsOn the other hand, granulators are used to create uniform granules before the tablet compression, which contributes to more consistent dosing and improved pill quality.

Please read carefully if you need to press tablets with moisture

Industrial tablet compacting machines with moisture

In addition, when the tablets contain a certain degree of moisture, machines are required that can handle this content without affecting product quality. This may involve adjustments in operating temperature and applied pressure, as well as modifications in the design of molds and dies. Proper selection and configuration of these machines is critical to ensure that the tablets not only meet size and shape specifications, but also structural integrity and proper release of the active ingredient. In short, choosing the right machinery and properly adapting it is key to success in the production of solid pills, especially when it comes to products that contain moisture.