Granulometry for compacting tablets: a practical guide for 3 to 10 t presses

Granulometry for compacting tablets: 3 t and 10 t presses

The PSD (Particle Size Distribution) determines whether a powder flows well and compacts without problems. In this guide you will see the size ranges (in microns, µm) recommended for 3-ton presses and 10 tons, and how to prepare them with powder mixers and oscillating crushers.

What do D10, D50 and D90 mean?

D10: : 10 % of the particles is minor that this size.

D50 (medium): 50 % of the particles is minor and the 50 % elderly.

D90: 90 % of the particles is minor that this size (controls the thick “tail”).

Recommended granulometry per press

| Press | Useful window (most dust) | Aim D50 | Limit D90 | Fine <150 µm | Explanation |

|---|---|---|---|---|---|

| 3 tons | 150–450 µm | 200–300 µm | ≤ 600–800 µm | ≤ 2–3 % | Somewhat finer powder (without excess fines) for good compaction with less available force. |

| 10 tons | 150–500 µm | 250–400 µm | ≤ 800–900 µm | ≤ 2–3 % | Slightly coarser particles are allowed due to the increased strength; keep fines under control. |

Useful shortcuts with sieves (approx.): 100 mesh ≈ 149 µm · 60 mesh ≈ 250 µm · 35 mesh ≈ 500 µm.

How to get to that PSD with your teams

1) Powder mixers (ribbon, V, double cone)

Aim: homogeneity + good flow + compressibility.

Recommended sequence: base → diluents/agglomerates → lubricant at the end (short mix) so as not to “soften” too much.

Checkpoint: finite <150 µm ≤ 2–3 % to avoid poor flow, weight variation and capping/lamination.

“Pill making machine, tablets, manual or automatic tablet press” has been added to your cart. View cart

“Pill making machine, tablets, manual or automatic tablet press” has been added to your cart. View cart

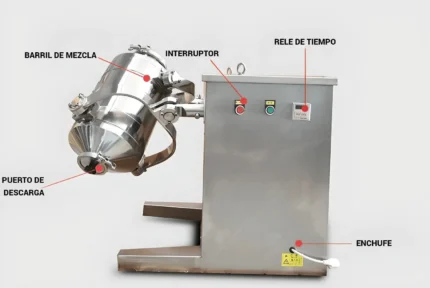

INDUSTRIAL MIXER MACHINE TUMBLER

4.741,60$ Taxes includedHIGH CAPACITY INDUSTRIAL V BLENDER MIXER

16.595,60$ Taxes included2) Oscillating crushers / granulators

Key use: give final shape to the distribution → the mesh selected sets the D90.

If D90 is passed, reduces mesh and sieve again; if there are many fines, mix with a 150–500 µm fraction or dust.

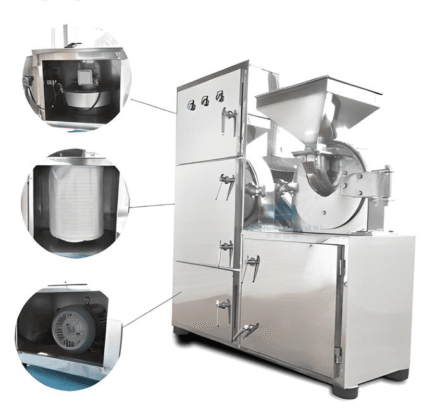

VITAMIN SUPPORT SUPPLEMENTS POWDER CRUSHER

7.112,40$ Taxes includedElectric grain mill 50 kg

3) Tablet presses (3 t and 10 t)

3 t: will appreciate a D50 200–300 µm and D90 ≤ 600–800 µm.

10 t: admits D50 250–400 µm and D90 ≤ 800–900 µm, always with few fine ones.

PROBIOTICS ONE-STROKE PRESSER

3.852,55$ Taxes includedEXTENDED RELEASE TABLET FORMING MACHINE

16.595,60$ Taxes includedPill making machine, tablets, manual or automatic tablet press

Rated 5.00 out of 5

1.991,47$ Taxes included

Quick process checklist

Flow: Check the hopper/auger; if you see “bridges,” there are too many fines or an unfavorable shape.

Lubricant (e.g. magnesium stearate): 0.5–1 % (up to 2 %) and short mix at the end.

Process humidity: controls to avoid “caking” and loss of hardness.

Validation: Make 2 batches per press with D50 slightly different (e.g., 220 vs. 280 µm at 3 t) and measures weight, hardness, friability and defects (capping).

Brief FAQ

Why not use “very fine” powder?

Because flows worse, generates weight variation and increases the risk of capping/lamination.

Can I use coarse grain with 10t?

Yes, within control: D90 ≤ 800–900 µm and very low fines.