Granulometry for compacting tablets: a practical guide for 3 to 10 t presses

Granulometry for compacting tablets: 3 t and 10 t presses

The PSD (Particle Size Distribution) determines whether a powder flows well and compacts without problems. In this guide you will see the size ranges (in microns, µm) recommended for 3-ton presses and 10 tons, and how to prepare them with powder mixers and oscillating crushers.

What do D10, D50 and D90 mean?

D10: : 10 % of the particles is minor that this size.

D50 (medium): 50 % of the particles is minor and the 50 % elderly.

D90: 90 % of the particles is minor that this size (controls the thick “tail”).

Recommended granulometry per press

| Press | Useful window (most dust) | Aim D50 | Limit D90 | Fine <150 µm | Explanation |

|---|---|---|---|---|---|

| 3 tons | 150–450 µm | 200–300 µm | ≤ 600–800 µm | ≤ 2–3 % | Somewhat finer powder (without excess fines) for good compaction with less available force. |

| 10 tons | 150–500 µm | 250–400 µm | ≤ 800–900 µm | ≤ 2–3 % | Slightly coarser particles are allowed due to the increased strength; keep fines under control. |

Useful shortcuts with sieves (approx.): 100 mesh ≈ 149 µm · 60 mesh ≈ 250 µm · 35 mesh ≈ 500 µm.

How to get to that PSD with your teams

1) Powder mixers (ribbon, V, double cone)

Aim: homogeneity + good flow + compressibility.

Recommended sequence: base → diluents/agglomerates → lubricant at the end (short mix) so as not to “soften” too much.

Checkpoint: finite <150 µm ≤ 2–3 % to avoid poor flow, weight variation and capping/lamination.

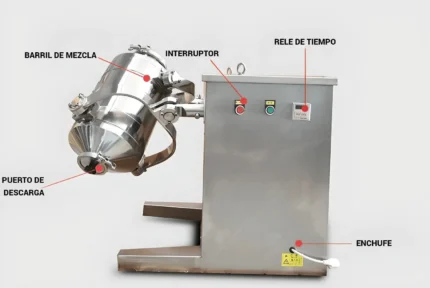

INDUSTRIAL MIXER MACHINE TUMBLER

4.714,40$ Taxes includedHIGH CAPACITY INDUSTRIAL V BLENDER MIXER

16.500,40$ Taxes included2) Oscillating crushers / granulators

Key use: give final shape to the distribution → the mesh selected sets the D90.

If D90 is passed, reduces mesh and sieve again; if there are many fines, mix with a 150–500 µm fraction or dust.

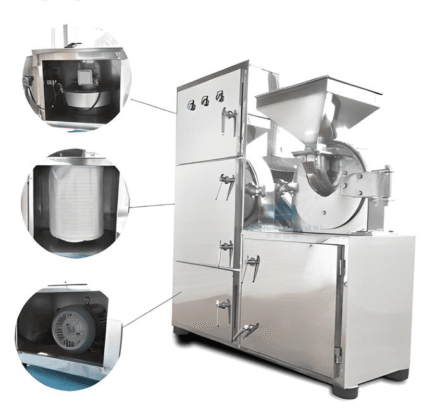

VITAMIN SUPPORT SUPPLEMENTS POWDER CRUSHER

7.071,60$ Taxes includedElectric grain mill 50 kg

3) Tablet presses (3 t and 10 t)

3 t: will appreciate a D50 200–300 µm and D90 ≤ 600–800 µm.

10 t: admits D50 250–400 µm and D90 ≤ 800–900 µm, always with few fine ones.

PROBIOTICS ONE-STROKE PRESSER

3.830,45$ Taxes includedEXTENDED RELEASE TABLET FORMING MACHINE

16.500,40$ Taxes includedPill making machine, tablets, manual or automatic tablet press

Rated 5.00 out of 5

1.980,05$ Taxes included

Quick process checklist

Flow: Check the hopper/auger; if you see “bridges,” there are too many fines or an unfavorable shape.

Lubricant (e.g. magnesium stearate): 0.5–1 % (up to 2 %) and short mix at the end.

Process humidity: controls to avoid “caking” and loss of hardness.

Validation: Make 2 batches per press with D50 slightly different (e.g., 220 vs. 280 µm at 3 t) and measures weight, hardness, friability and defects (capping).

Brief FAQ

Why not use “very fine” powder?

Because flows worse, generates weight variation and increases the risk of capping/lamination.

Can I use coarse grain with 10t?

Yes, within control: D90 ≤ 800–900 µm and very low fines.