INDUSTRIAL LABELLING MACHINE FOR 5 LITRE BOTTLES AND CARABS

17.086,16$ Taxes included

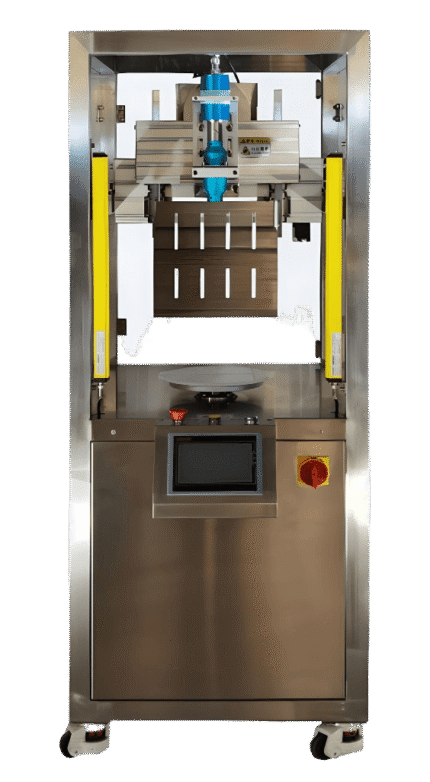

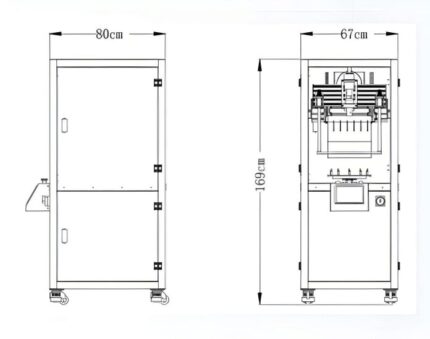

Protein Fortification Tablet Press Machine

22.393,40$ Taxes included

Industrial linear chicken breast cutting machine

16.995,41$ Taxes included

The set of four Linear diced chicken breast cutting machines operates as a unified system, transforming the breasts into regular cubes. This process takes place in successive stages: first, a horizontal cut to obtain fillets; then, the cut these chicken fillets into strips; followed by the dicer; and finally, the classification according to size. Designed to work in harmony, these machines facilitate agile, high-quality production. Thanks to their automation and precision, the need for manual handling is reduced, ensuring greater consistency in the finished product.

SKU:

AR10600

Category: Accessories

Description

LINEAR CHICKEN BREAST DICING MACHINE

The Linear dicer for chicken breasts represents a solution industrial advanced and optimized for efficient and homogeneous food processing. This equipment is composed of four key components, each dedicated to a different phase of the cutting and sorting process. The cut chicken breast into cubes It is carried out by a series of specialized industrial machines that work together to achieve the desired final product.

Next we will delve into the operation of these four fundamental machines, all meticulously designed for precise cutting in fresh chicken breast cubes.

1. HORIZONTAL CHICKEN BREAST FILLETTING MACHINE

The main cutting machine is the starting point of the process, making an initial horizontal cut in the fillets. This machine stands out for its versatility, allowing various types of cuts using customizable blades. These blades can be adjusted for cuts of different thicknesses, varying from 3 mm to 50 mm, thus adapting to the specific needs of each operation. Once this initial stage is completed, the fillets They are efficiently transported via a conveyor belt to the next cutting machine, ensuring a continuous and optimized workflow.

| MODEL | FQARC200 |

| MATERIAL | Stainless steel and waterproof (SUS 304)

silicone sealants |

| CONVEYOR BELT | 160mm wide |

| BELT SPEED | 3 – 15 meters per minute |

| CUT SIZE | 3 – 5 mm |

| CUTTING SPEED | 60 pieces per second |

| RAW MATERIAL WIDTH | 140 mm |

| POWER | 1.29 KW |

| STRAIN | 220 V – 380V |

| SIZE | 1780 mm long

900 mm wide 1430 mm high |

| REFERENCE | AR10600 |

LINEAR CHICKEN BREAST STRIPPING MACHINE

During the next phase, the second strip cutting machine plays a crucial role in turning the fillets into strips. This machine has the functionality to adjust the thickness of the strips between 5mm and 45mm, allowing for precise adaptation to product specifications. Process efficiency is constantly preserved as the product progresses to the third cutting machine, thus ensuring an uninterrupted workflow and high quality at every stage of the process.

| MODEL | QTART300 |

| MATERIAL | Stainless steel and waterproof (SUS 304)

silicone sealants |

| CONVEYOR BELT | 300 mm |

| BELT SPEED | 3 – 18 meters per minute (adjustable) |

| CUT SIZE | 5 – 45mm (70mm adjustable) |

| CUTTING SPEED | 300 – 500 kilos per hour |

| RAW MATERIAL | 300 mm |

| STRAIN | 220 V – 380 V |

| POWER | 1.50 KW |

| SIZE | 1500mm long

640 mm wide 1000 mm high |

LINEAR CHICKEN BREAST DICING MACHINE

At the end of the process of cutting the chicken strips, a professional is responsible for carefully manipulating the position of the strips, rotating them 180 degrees to ensure a uniform and precise cut. The last cutting machine takes center stage. Its function is to make the final cut, transforming the strips into dice whose dimensions can vary between 4mm and 45mmThis final step is crucial to obtaining a product that meets the required quality and precision standards.

| MODEL | HKARTJ-350 |

| MATERIAL | Stainless steel and waterproof (SUS 304)

silicone sealants |

| CONVEYOR BELT | 350 mm |

| CUTTING WIDTH | 200 mm |

| ENTRY HEIGHT | 1050 mm |

| OUTLET HEIGHT | 1050 mm |

| DICE SIZE | 4 mm |

| POWER | 1.1 KW |

| STRAIN | 220 V – 380V |

| CUTTING CAPACITY | 500 kilos per hour |

| SIZE | 1500 mm long

500 mm wide 1300 mm high |

LINEAR SIEVE AND CLASSIFIER FOR CHICKEN BREAST DICE SIZE

After the cutting process is completed, the products move to the next phase along the conveyor belt. Here, an important stage of processing takes place. screening and classification. During this process, products are carefully separated according to size, ensuring accurate and uniform grading. For this purpose, a maximum limit of 1000 kg is set. 45 mm, ensuring that each piece meets the criteria of size established for their proper classification.

| MODEL | HKARC-620 |

| MATERIAL | The whole machine is made of 304 steel, the seals and gaskets of the machine are made of food grade silicone. |

| STRUCTURE | A belt with two discharge ports |

| VIBRATION SOURCE | 2 vibration motors |

| POLISHED | Stainless steel parts are polished inside and out |

| VOLTAGE | 380V 50HZ |

| POWER | 2.2 KW |

| MESH FRAME | Mesh with hook plate, with custom holes |

| SCREENING RANGE | From 15 mm to 45 mm |

| SIZE | 2500mm long

650mm wide 1300mm high |

| REFERENCE | AR10603 |

Reviews (0)

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.