Machine for cutting pork loin or fresh meat into fillets

6.736,26$ Taxes included

Pill and capsule counting machine, all sizes and diameters, customized

3.202,68$ Original price was: 3.202,68$.3.119,95$Current price is: 3.119,95$. Taxes included

Filtration machine, microfiltration and ultrafiltration of liquids

34.863,10$ Taxes included

Filtration Machine for the Pharmaceutical and Biotechnology Industry

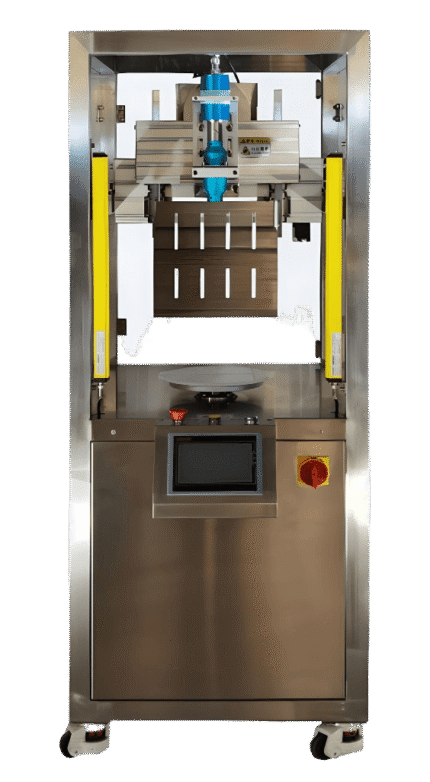

Our Filtration Machine is designed to meet the highest purity standards in pharmaceutical, cosmetic and biotechnological processes. Thanks to its advanced technology, you will be able to cover everything from Coarse Filtration until Ultrafiltration, all in one versatile team. In addition, we have Custom Ceramic Membrane Filters, tailored exactly to your filtration requirements.

SKU:

AR10545

Category: Accessories

Description

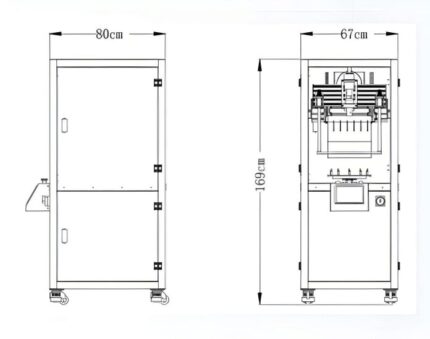

Filtration, Microfiltration and Ultrafiltration Machine for Liquids and Viscous

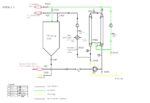

Discover our innovative Filtration Machine, specially designed to process a wide range of fluids, from aqueous solutions to media with high viscosity. Thanks to its interchangeable modules of Microfiltration and UltrafiltrationThis equipment guarantees top quality results in the pharmaceutical, cosmetic and food sectors.

Our advanced technology allows you to optimize the separation of particles, bacteria and macromolecules according to the requirements of each project. This way, you can process liquids and viscous products (such as concentrated serums or dense formulations) with total precision and efficiency. With customized adjustments to the pore size and resistance of the filters, you ensure continuous and reliable operation, saving costs and time on your production line.

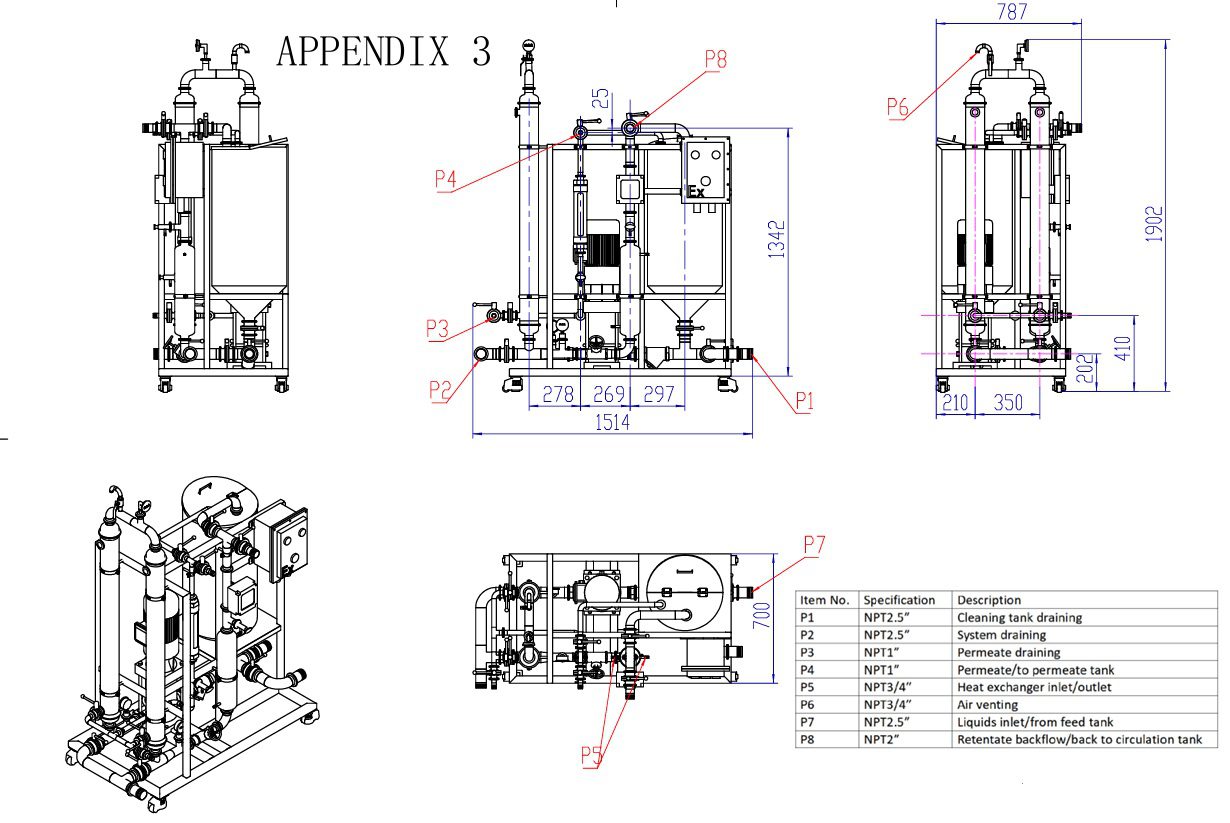

Technical specifications of the ARDLF8-40 model

| Item Number | Name | Specification | Material | Amount |

|---|---|---|---|---|

| Yo | Filter | |||

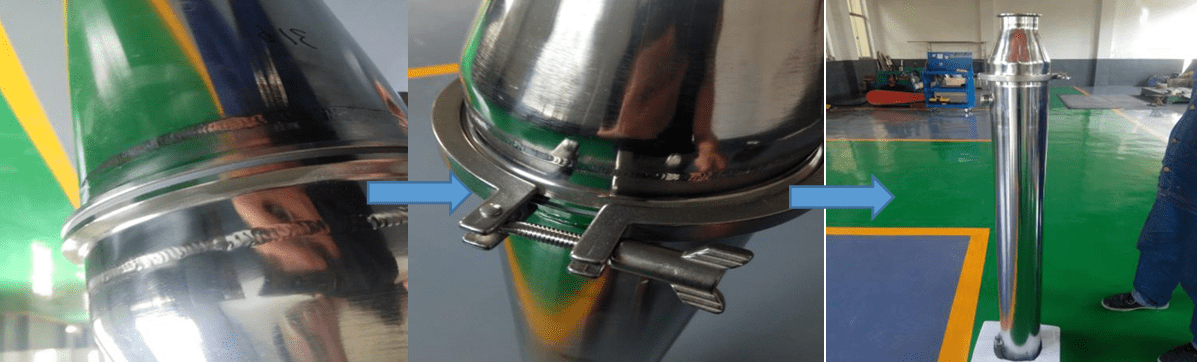

| 1 | Stainless steel housing | DARQH-301200-3 | SS304 or 316 | 2 pcs |

| 2 | Membrane element | CM3019041200/20nm | ceramic | 6 pcs |

| II | Pump (explosion-proof motor) | |||

| 1 | CARDLF8-40 | 1.5kw | SS304 or 316 | 1 pc |

| III | Tank | |||

| 1 | Cleaning tank | 100L | SS304 or 316 | 1 pc |

| IV | Instrument | |||

| 1 | Flow meter | Concentrate: 1.6-16m³/h / FI01 | SS304 or 316 | 1 pc |

| 2 | Flow meter | Permeate: 40-400L/h / FI02 | Glass | 1 pc |

| 3 | Pressure gauge | 0-1MPa / PG01, PG02 | SS304 or 316 | 2 pcs |

| 4 | Thermometer | 0-150℃ / TG01 | SS304 or 316 | 1 pc |

| V | Valve system | |||

| 1 | Filter valve | V01-02 | SS304 or 316 | 1 batch |

| 2 | Cleaning valve | CV01-03 | SS304 or 316 | 1 batch |

| 3 | Permeate valve | PV01-04 | SS304 or 316 | 1 batch |

| 4 | Drain valve | DV01-04 | SS304 or 316 | 1 batch |

| 5 | Pressure adjustment valve | FV01 | SS304 or 316 | 1 pc |

| 6 | Vent valve | VV01 | SS304 or 316 | 1 pc |

| 7 | Sampling valve | concentrate+permeate | SS304 or 316 | 2 pcs |

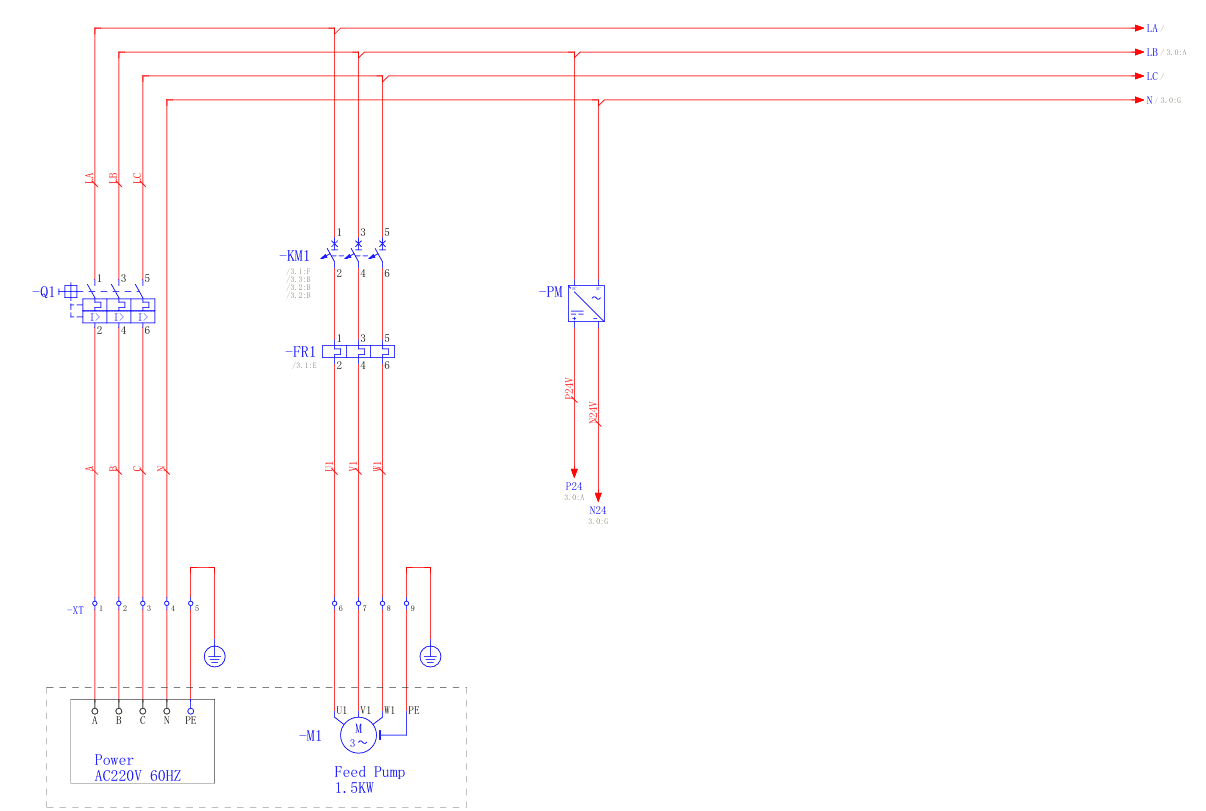

| VI | Control system | |||

| 1 | control Panel | Ex-proof | 1 pc | |

| 2 | Accessories | 1 set | ||

| VII | Pipe system | |||

| 1 | Security filter | And style | SS304 or 316 | 1 pc |

| 2 | Heat exchanger | 0.5m² | SS304 or 316 | 1 pc |

Instruction Manual

For more detailed information on the operation and maintenance of the Filtration, Microfiltration and Ultrafiltration Machine for Liquids and Viscous ARDLF8-40, see the following link:

ARDLF8-40 Instruction Manual

Coarse Filtration Machine (1–5 µm [micrometers])

- Large particle retention: ideal for sediments, tissue remains and microcrystals.

- Basic visual clarity: Suitable for slightly cloudy liquids, although it does not remove bacteria or fine particles.

- Preliminary processes: the Coarse Filtration It is the first step to reduce turbidity before moving on to more precise stages.

Fine Microfiltration Machine (0.2–0.45 µm [micrometers])

- Elimination of bacteria and very small particles: Its high precision retains contaminants typical of delicate processes.

- Almost sterile product: With a 0.2 µm (micrometer) absolute filter, a degree of sterility widely used in the production of injectables and sterile pharmaceutical products is achieved.

- Excellent visual clarity: The resulting liquid is very clear, meeting the strictest quality requirements.

Ultrafiltration Machine (< 0.1 µm [micrometers])

- Retention of macromolecules: Depending on the “cut-off” in kDa (kilodaltons), it is possible to separate proteins, polysaccharides and other colloids.

- Advanced Purification: Beyond simple visual clarification, the Ultrafiltration allows to isolate or concentrate compounds of interest (for example, collagen or specific peptides).

- Removal of submicron contaminants: provides ultrapure filtration, essential in the production of highly demanding drugs and biologicals.

Custom Ceramic Membrane Filters

- Adaptability to each process: Our ceramic membrane filters are custom designed according to pore size, flow rate and chemical resistance required.

- Long service life and high strength: Ceramic offers durability against high temperatures and aggressive chemical agents.

- Application versatility: available for Coarse Filtration (1–5 µm [micrometers]), Fine Microfiltration (0.2–0.45 µm [micrometers]) and Ultrafiltration (< 0.1 µm [micrometers]), guaranteeing complete coverage of your needs.

What level of filtration do you need?

Tell us about your process and we'll guide you to choose the perfect combination of filters and settings. With our Filtration Machine and the Custom Ceramic Membrane Filters, you will be able to optimize your purification procedures to the maximum, ensuring the highest quality of your products and complying with the most demanding regulations in the sector.

ARC Distribution, a leading manufacturer of specialized machinery for the pharmaceutical sector, offers its solutions in 17 countries of the European Union: Germany, Austria, Belgium, Czech Republic, Spain, Estonia, France, Hungary, Italy, Latvia, Lithuania, Luxembourg, Netherlands, Poland, Portugal, Slovakia and Slovenia. All our equipment has a 2 year warranty and we have Delivery service with installation (additional) to ensure that your project is launched as efficiently as possible.

Warranty and Preventive Maintenance

In ARC Distribution We support the quality of our machines with a 2 year warrantyFor more information, visit:

ARC Distribution Guarantee

In addition, we offer a service of Preventive Maintenance, contracted additionally, which ensures optimal operation and prolongs the useful life of your equipment. Find out more details at:

ARC Preventive Maintenance

Contact us and discover the new era of pharmaceutical and biotechnology filtration! With ARC Distribution You will have the best technology and support to boost the quality of your products globally.

Reviews (0)

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.