Instruction Manual: Industrial Animal Bone Crusher

Official manual for the Professional Bone Crusher – Industrial solution for bone processing in the food industry

I. Basic Structure and Specifications

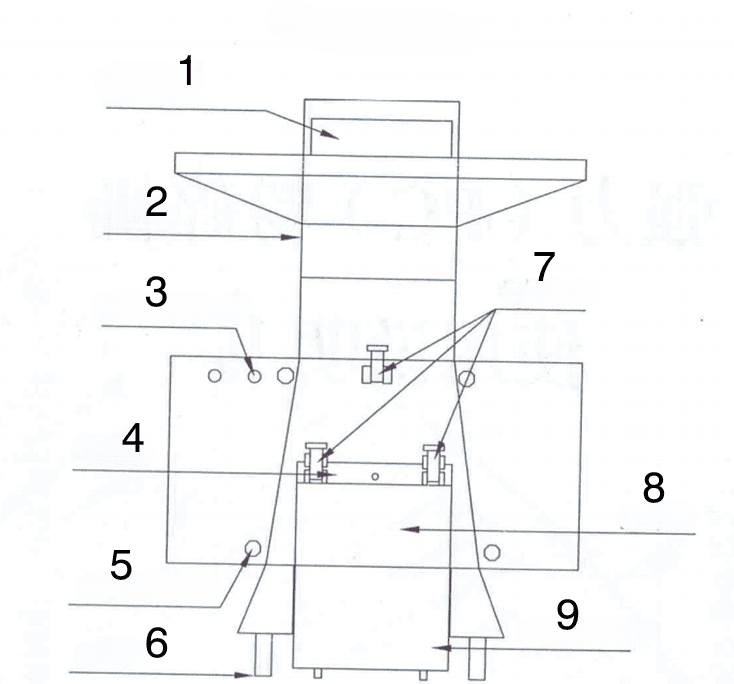

Image 1: Front view of the industrial bone crusher – Control panel and feeding system

- (Power input)

- (Top of container)

- (Start/Stop Button)

- (Mesh frame)

- (Square locking screw)

- (Steering wheel)

- (Lock nut)

- (Material output)

- (Stainless steel hopper)

Applications and Technology

The bone crusher It is specially designed for crushing dry bones, fresh beef big bones, pig bones, lamb bones, donkey bones and various kinds of animal bones and fish bones. The crushing range is 3-100mm.

This equipment is widely used in the production of:

- ✓ Meat products: Sausages, cold cuts, meat for lunch

- ✓ Soup base: Bone broths, bone marrow extracts

- ✓ Nutrition products: Bone meal, gelatin, chondroitin, bone peptides

- ✓ Processed foods: Instant noodles, extruded foods, compound seasonings

- ✓ Animal feed: Pet food and frozen meat products

Main Features

- Type of cut: The shear type crusher is suitable for crushing various hard materials.

- Versatility: Perfect for coarse grinding of conventional materials.

- Personalization: Design of special feed gates and different sieve mesh sizes according to customer needs, adapting to various types of materials and particle size requirements.

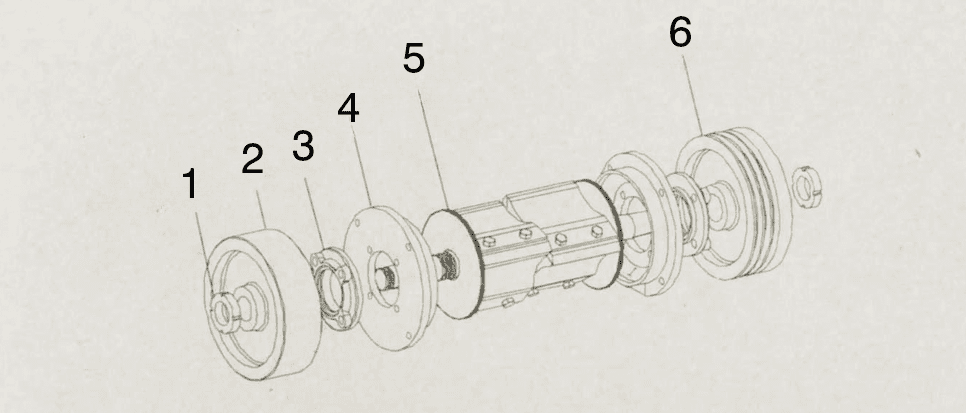

Image 2: Internal view of the shredder – Blade system and shredding mechanism

- (Lock nut)

- (Steering wheel)

- (Bearing cap)

- (Bearing)

- (Blade body, main shaft assembly)

- (Pulley)

Installation and Use Instructions

Warning: Please read these instructions carefully before using the bone crusher. Proper installation will ensure the safety of your staff and the optimal operation of the equipment.

- Electrical connection: The machine uses a three-phase four-wire system (it is mandatory to connect the neutral wire). Before powering on, open the feed hopper to check whether there are any foreign objects in the crushing chamber.

- Address verification: Start the machine with no load to check if the blades are rotating in the correct direction. If they are rotating in the opposite direction, exchange any two phase wires. Once the correct direction is confirmed, tighten the feed hopper lock nut and start production.

- Important precautions:

- It is prohibited to introduce hard metal objects into the grinding chamber.

- If you detect abnormal noises, immediately stop the machine, identify the cause and solve the problem before restarting.

- It is recommended to install the machine in a separate work area.

Maintenance and Care

- Engine ventilation: Place the starter motor of the machine in a ventilated position to ensure heat dissipation and prolong the service life of the motor.

- Blade Review: Check the bolts of the blades regularly. After using a new machine for a week, use a special tool to tighten the bolts of the movable blades, strengthening the fixation between the blades and the bracket.

- Lubrication: For supported bearings, add grease to the nipples every 20 days to ensure lubrication between the bearings.

- Sharpening blades: To ensure cutting efficiency, regularly inspect the moving blades according to the conditions of use. Keep the blades sharp to avoid unnecessary damage to other components.

- Cleaning: Before the second start, clean out any crushed material residue left in the chamber after the first operation to reduce starting resistance and engine load. Periodically remove the flywheel and pulley covers to clean the dust outlet under the flange.

- Replacing blades: When replacing blades, keep a cutting gap between them of about 0.5-0.8mm.

- Belt Check: Check the belts regularly for slack. If so, loosen the engine mounting bolts and use a special tool to move the engine outwards until the belts are taut.

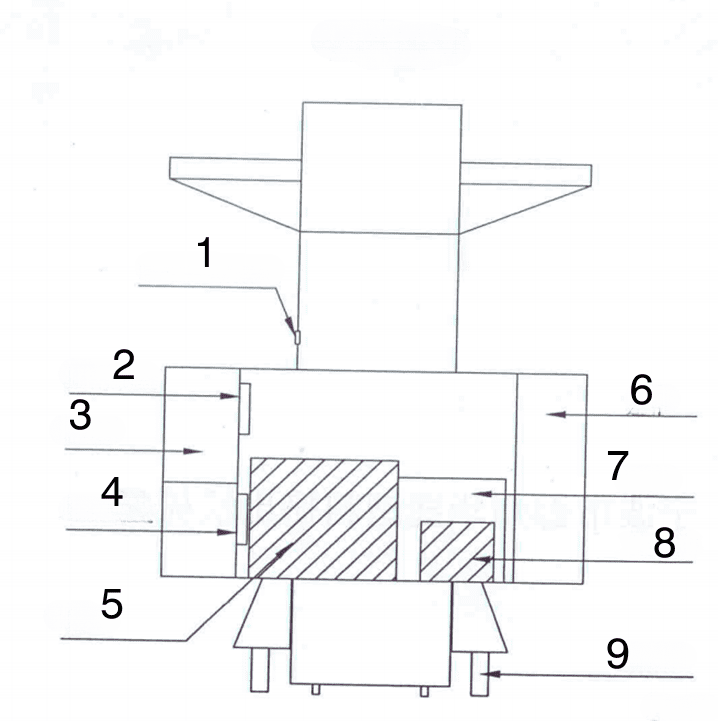

Image 3: Rear view – Transmission system, engine and maintenance components

- (Upper box support point)

- (Large belt pulley)

- (Side cover)

- (Small belt pulley)

- (Engine)

- (Square placement)

- (Gray cover)

- (Starter)

- (Universal/Multi-directional wheel)

Technical Support and Warranty

Do you have questions about how to use your bone crusher to optimize your industrial production? ARC Distribution is here to help you.

Exclusive 2 Year Warranty

All bone crushers distributed by ARC Distribution They have a Full 2 year warranty covering manufacturing and operating defects, giving you complete peace of mind for your industrial investment.

Technical Service Throughout Europe

ARC Distribution offers specialized technical service in all European countries, guaranteeing close support regardless of your location:

Spain

Portugal

France

Italy

Germany

United Kingdom

Ireland

Belgium

Netherlands

Luxembourg

Denmark

Sweden

Finland

Austria

Greece

Cyprus

Malta

Poland

Czech Republic

Slovakia

Hungary

Slovenia

Croatia

Romania

Bulgaria

Estonia

Latvia

Lithuania

Find Your Nearest Technical Service

To find the technical service center closest to your industrial facility, visit our technical service finder by map, where you can easily locate support available in your region.

Complete range of industrial shredders

The bone crusher is part of our wide range of solutions for industrial processing. ARC Distribution offers equipment for all needs:

Meat Industry

Specific shredders for processing meat and bones in the production of sausages.

Food Production

Equipment for grinding raw materials in the production of processed foods.

Supplements Industry

Crushers for the production of bone-based nutritional supplements.

Petfood Industry

Specialized equipment for the production of pet food.

Industrial Restoration

Solutions for processing raw materials in large-scale catering services.

Explore our Full range of industrial meat machinery including meat mincers, slicers for fresh or frozen meat and dicing machines.

For technical support, spare parts inquiries, or industrial application advice, please visit https://distribucionarc.com/producto/trituradora-de-huesos-industrial/ or contact our team specializing in solutions for the food industry.