Instruction Manual: Automatic Can Sealer for Soft Drinks and Soft Drinks

Official manual for the ARCCLA20 Automatic Control Can Sealer – The professional solution for sealing beverages in restaurants, cafes and bars

Welcome to the User

Dear restaurant, cafe or bar owner:

Thank you for purchasing our Automatic Control Can Sealer, the perfect tool to offer cold drinks and soft drinks in professionally sealed containersThis equipment will allow you to expand your takeaway beverage offering, increasing both customer satisfaction and your business options.

The ARCCLA20 Can Sealer It is specifically designed for hospitality establishments that wish to offer soft drinks, cocktails, craft beverages, cold brew, iced teas and other cool drinks in hygienically and professionally sealed cans.

Warning: Before installing and using your beverage can sealer, please read this manual carefully. Proper installation will ensure the safety of your staff and the optimal operation of the equipment.

Note: Due to continuous improvement of our products, the can sealing machine you have purchased for your catering establishment may differ slightly from the images shown in this manual. Please refer to the actual product.

Safety Precautions for Your Establishment

To ensure safety in your restaurant, cafe or bar when using the can sealer:

- Electrical requirements: Use a 220V 50/60Hz power outlet. Install the machine in a dry area of your bar or kitchen, away from areas with water splashes.

- Electrical protection: The power outlet must be grounded to prevent electrical shocks that could affect your personnel.

- Proper wiring: Check that all electrical connections are correct. Do not modify the original wiring to avoid risk of fire, shock or failure during service.

- Team Safety: Do not open the back cover of the sealer, there is a risk of electric shock which could interrupt your beverage service.

- Injury Prevention: During operation, instruct your personnel not to touch the sealing rollers and pressure head with their hands.

- Cable Care: Do not bend, overstretch, twist, coil or damage the power cord. Use a dedicated circuit for the sealing machine. For replacements, purchase original components from the manufacturer.

- Adequate space: Reserve a dedicated space for the can sealer on your counter or preparation area and do not place other objects on top of it that could interfere with its operation.

Daily Maintenance in your Establishment

To ensure that your beverage can sealer works perfectly during service hours:

- Routine cleaning: Incorporate can sealer cleaning into your establishment's daily closing routine.

- Critical components: The rollers and the pressure head must be kept particularly clean to ensure a perfect seal on your drinks. This is crucial to maintaining the quality and freshness of your bottled soft drinks.

Troubleshooting Common Problems During Service

Important: Always disconnect power before servicing the sealer.

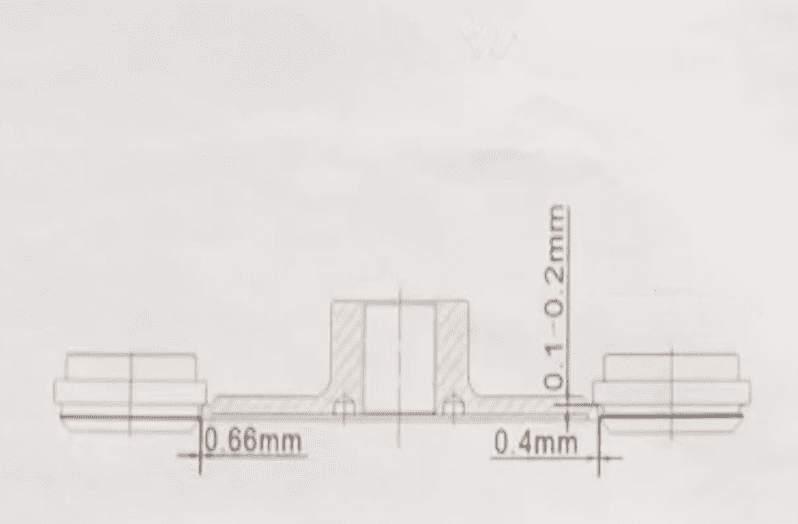

The diagram is the technical plan showing the correct position of the heads:

- A side view of what appears to be a sealing process

- A central element called (pressure head)

- Accurate distance measurements:

- 0.66mm to the left

- 0.1-0.2mm in the center

- 0.4mm to the right

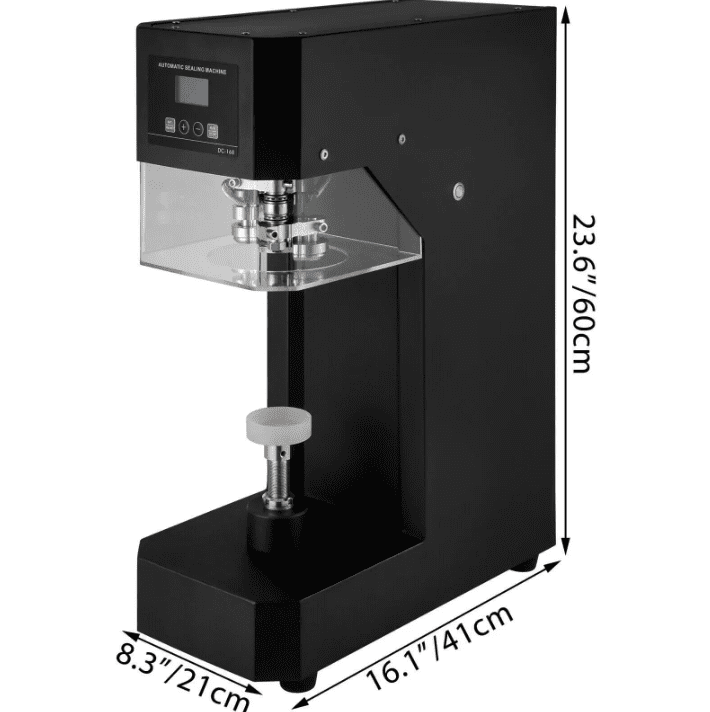

Figure 1: Diagram of main components of the ARCCLA20 can sealer

The sealer screen does not turn on

Possible causes and solutions:

- Power cord disconnected or plug loose. Check connections at installation area.

- Internal control cable disconnected. Check internal connections if you are technically savvy.

- Main board damaged, contact technical service for replacement.

The rollers on the sealer are not working

Possible causes and solutions:

- Main motor cables disconnected. Check internal connections (red and black cables).

- Main motor defective, contact technical service.

The sealer runs continuously without stopping.

Possible causes and solutions:

- Problems with the travel switch. Check internal connections.

- Incorrect travel switch adjustment. Readjust the distance between the switch and the cam.

- Faulty operating switch, requires replacement.

Beverage cans do not seal properly or leak

Possible causes and solutions:

- Improper tray adjustment. Readjust the rod height so that the lid and pressure head fit properly.

- Incorrect gap between roller and head. For a perfect seal of your drinks, keep a gap of 0.1-0.2mm.

- Incorrect distance between rollers and head. Adjust according to the diagram included.

Technical Specifications of the Beverage Can Sealer

| Model: | ARCCLA20 – Can Sealer for Hospitality |

| Feeding: | 220V/50Hz |

| Engine power: | 200W |

| Ability: | Cans 30-170mm high (compatible with standard beverage formats) |

| Net weight: | 36kg |

| Dimensions: | 430×260×615mm (ideal for bars and work spaces in hospitality) |

Operating Procedure for Sealing Beverages

- Facility: Place the sealer on a flat, stable surface in your beverage preparation area.

- On: Connect the power and turn on the display.

- Initial test: Press the green start switch to verify proper operation before service. The LED light will illuminate during operation.

- Beverage sealing: Place the can with your drink and lid on the tray, press the start switch. The machine will automatically seal and stop when finished. Remove the perfectly sealed drink can.

- Emergency stop: If any abnormality occurs during service, press the red stop button and refer to the troubleshooting guide.

- Counter reset: To reset the production counter (useful for beverage inventory), press the emergency stop button for 10 seconds.

Adjusting the Sealer for Different Beverage Can Formats

- Height adjustment for different cans:

- Loosen the roller eccentric shaft locking screw with M6 hex key.

- Adjust the height of the roller according to the can format you use in your establishment.

- Retighten the screw once it is properly adjusted.

- Sealing pressure adjustment:

- Loosen the locking screw with M6 hex key.

- Use a #12 open-end wrench to adjust the roller eccentric shaft.

- Find the optimal pressure for a perfect seal depending on the type of beverage and can format.

- Retighten the locking screw.

The diagram shows:

- The vertical structure with three main sections

- At the top there is an element called (tray or platform, upper die)

- In the central part there is an element (adjustment needle or adjustment pin) saw key chuck

- Structural lower part

Advantages of the ARCCLA20 Can Sealer for your Hospitality Business

- ✓ Expand your on-the-go beverage offering: Offer Soft drinks, cold brews, iced teas and cocktails professionally sealed.

- ✓ Optimal conservation: Sealed drinks maintain their freshness, carbonation and flavor for longer.

- ✓ Differentiation: Impress your customers with bottled beverages under your own brand.

- ✓ New lines of business: Develop a line of exclusive bottled beverages for direct sale.

- ✓ Hygiene guaranteed: Professional sealing ensures maximum hygiene for your drinks.

Recommendations for Use in Hospitality

- Use the can sealer to package your homemade soft drinks, cold brews, kombuchas and other specialty beverages.

- Customize cans with your establishment's labels to reinforce your brand.

- Offer grab-and-go packs with selections of your top-rated bottled beverages.

- Set up a direct sales corner for your sealed drinks for customers who want to take them home.

Technical Support and Warranty

Do you have questions about how to use your can sealer to maximize beverage sales in your establishment? ARC Distribution is here to help you.

Exclusive 2 Year Warranty

All can sealers ARCCLA20 distributed by ARC Distribution They have a Full 2 year warranty which covers manufacturing and operating defects, offering you complete peace of mind for your investment.

Technical Service Throughout Europe

ARC Distribution offers specialized technical service in all European countries, guaranteeing close support regardless of your location:

Spain

Portugal

France

Italy

Germany

United Kingdom

Ireland

Belgium

Netherlands

Luxembourg

Denmark

Sweden

Finland

Austria

Greece

Cyprus

Malta

Poland

Czech Republic

Slovakia

Hungary

Slovenia

Croatia

Romania

Bulgaria

Estonia

Latvia

Lithuania

Find Your Nearest Technical Service

To find the service center closest to your establishment, visit our technical service finder by map, where you can easily locate support available in your region.

Complete Range of Can Sealers for All Sectors

The sealer ARCCLA20 is part of our wide range of solutions for can sealing. ARC Distribution offers equipment for all needs:

Hospitality Sector

Compact models ideal for bars, restaurants and cafes.

Industrial Sector

High capacity sealers for production lines.

Large Format Preserves

Specific solutions for sealing larger cans.

Craft Drinks

Equipment adapted for microbreweries and artisan producers.

Food Industry

Sealers that comply with specific health regulations.

Explore our Full range of can sealers and find the model that best suits the needs of your business.

For technical support, spare parts inquiries, or advice on sealing machine applications in your business, visit https://distribucionarc.com/producto/selladora-de-lata-control-automatico/ or contact our team specializing in hospitality solutions.

This manual is optimized for the ARCCLA20 Can Sealer, ideal for restaurants, cafes and bars that wish to offer soft drinks and fresh beverages in a professionally sealed format. ARC Distribution – Your technological partner in sealing solutions for hospitality and industry.