Instruction Manual: VAR-180 Electric Can Sealer

Instruction Manual: VAR-180 Electric Can Sealer

Official manual for the VAR-180 Electric Can Sealer – Professional solution for can sealing in the food and beverage industry

I. General Description

The VAR-180 electric can seamer has been developed by our factory according to the practical requirements of our customers. It is based on the pneumatic seamer model, to which electric functionality has been added to achieve automatic can sealing. This increases production efficiency, reduces labor intensity for operators, and ensures higher reliability in sealing quality.

This machine is suitable for sealing bottoms and tops of paper cans, ring-sealed cans and three-piece cans. It is an ideal equipment for small food and beverage factories, as well as an excellent backup equipment for medium and large factories in the sector.

II. Structural Characteristics and Operating Principle

This machine is composed of base, drive system, rotary head, sealing blades, adjusting device and electrical system. The sealing blades can be adjusted within a certain range, so by changing the pressing head, cans of various diameters can be sealed. In addition, by adjusting the height regulating device, cans of different heights can be sealed.

During operation, the can with the lid attached is placed on the tray. When the switch is activated, the tray automatically rises. The pressure head and the tray hold the can firmly and rotate together, thus completing the sealing process.

III. Main Technical Specifications

| Production efficiency: | 800-1200 cans/hour |

| Suitable can diameter: | φ50~φ180mm (especially large cans can be made to order) |

| Suitable can height: | 55~300mm (especially tall cans can be made to order) |

| Power supply: | 50HZ, 220V 250W or 50HZ, 380V 250W |

| External dimensions: | 800×550×1500mm |

| Equipment weight: | 100kg |

| Head rotation speed: | 900 rpm |

IV. Steps for Adjustment and Operation

Important note: For a better understanding of the adjustment procedures, it is recommended to refer to the reference video mentioned in the manual.

Step 1: Adjustment and checking the concentricity between the tray and the pressure head

- Place the ring lid on the can and position it in the center of the tray.

- Lift the tray and carefully check whether the ring cover fully engages with the pressure head.

- If there is any deviation, adjust the base slightly.

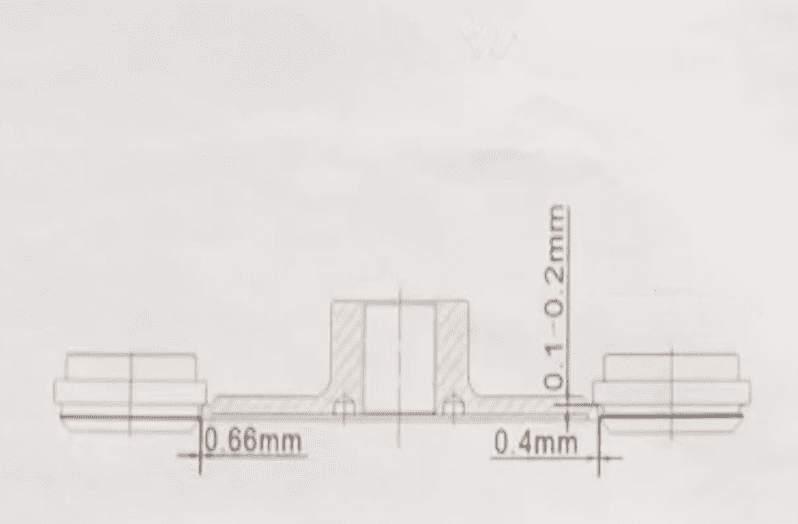

The diagram is the technical plan showing the correct position of the heads:

- A side view of what appears to be a sealing process

- A central element called (pressure head)

- Accurate distance measurements:

- 0.66mm to the left

- 0.1-0.2mm in the center

- 0.4mm to the right

Step 2: Adjusting the tray height

- Pull the tray up to its highest point.

- Place an empty can next to the tray and check the distance between the lid and the pressure head. It should protrude by approximately 5 mm.

- If the height is not suitable, please adjust the lifting seat. (Please refer to the operation video)

Step 3: Adjusting the distance between the first winding blade and the pressure head

- Manually pull the blade arm so that the blade approaches the center of the pressure head.

- Visually inspect the gap between the blade and the pressure head. There should be a minimum distance of 1 mm.

- If the distance is not correct, please adjust the diameter changing screw. (Please refer to the operation video)

Step 4: Adjusting the distance between the second forming blade and the pressure head

- Manually pull the blade arm so that the blade approaches the center of the pressure head.

- Visually inspect the gap between the blade and the pressure head. There should be a minimum distance of 1 mm.

V. Precautions for Use and Maintenance

- Before use, please tighten the left and right wheels against the sealing pad and clean the lifting work table.

- Apply lubricating oil to all moving parts (sewing machine oil or motorcycle engine oil).

- If any abnormality is detected, immediately stop the machine for inspection and troubleshooting.

- Be sure to properly connect the ground wire!

Technical Support and Warranty

Do you have questions about how to use your can seamer to maximize your production? ARC Distribution is here to help you.

Exclusive 2 Year Warranty

All can seamers VAR-180 distributed by ARC Distribution They have a Full 2 year warranty covering manufacturing and operating defects, giving you complete peace of mind for your industrial investment.

Technical Service Throughout Europe

ARC Distribution offers specialized technical service in all European countries, guaranteeing close support regardless of your location:

Spain

Portugal

France

Italy

Germany

United Kingdom

Ireland

Belgium

Netherlands

Luxembourg

Denmark

Sweden

Finland

Austria

Greece

Cyprus

Malta

Poland

Czech Republic

Slovakia

Hungary

Slovenia

Croatia

Romania

Bulgaria

Estonia

Latvia

Lithuania

Find Your Nearest Technical Service

To find the service center closest to your establishment, visit our technical service finder by map, where you can easily locate support available in your region.

Full Range of Can Sealers

The can seamer VAR-180 is part of our wide range of solutions for industrial sealing. ARC Distribution offers equipment for all needs:

Semi-automatic closing machines

Ideal for small and medium productions with excellent value for money.

Automatic Closing Machines

For industrial production with high performance and minimal operator intervention.

Pneumatic Sealers

Special for specific environments that require compressed air systems.

Explore our Full range of can sealers and find the model that best suits the needs of your business.

For technical support, spare parts inquiries, or industrial application advice, please visit https://distribucionarc.com/producto/cerradora-de-latas-var-180/ or contact our team specializing in solutions for the food industry.