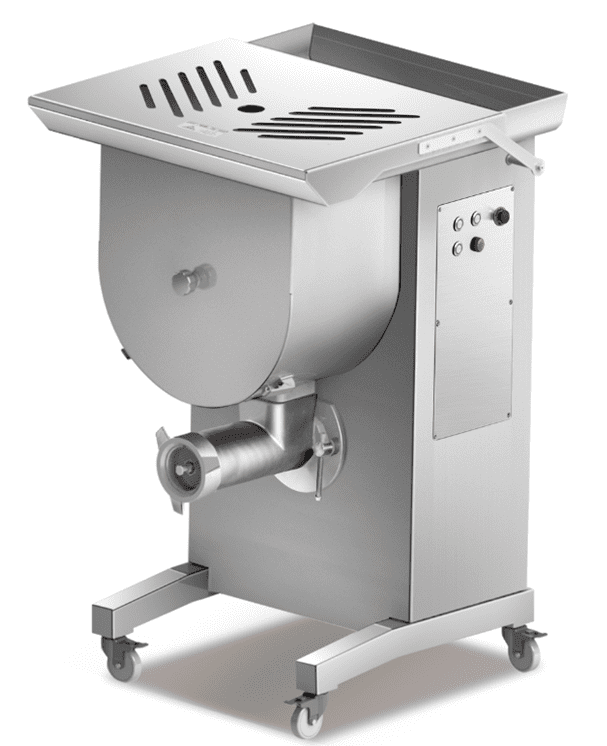

Instruction Manual: DMX-32A Meat Grinder and Mixer

Instruction Manual: DMX-32A Meat Grinder and Mixer

Official manual for the DMX-32A Industrial Meat Grinder with Mixer – Professional solution for meat processing in the food industry

I. Introduction

The DMX-32A meat mincer and mixer is the best combination of high performance, superior quality and low energy consumption. It can be used to process pork, beef, fatty meat, mixed meats, fish and lamb.

Main features:

- ✓ Professional meat mincing and mixing

- ✓ Processing under hygienic conditions

- ✓ Low energy consumption

- ✓ Power reducer

- ✓ Robust structure in AISI 304 stainless steel

This manual includes operating, cleaning and troubleshooting instructions.

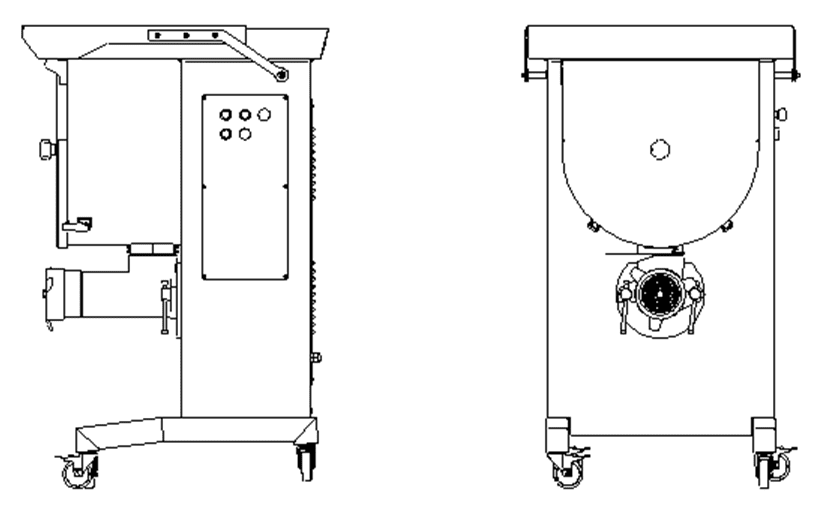

II. Technical Specifications

| Model: | DMX-32A |

| Voltage: | 380V/50Hz |

| Chopping power: | 3KW |

| Performance: | 800-1000kg/h |

| Plates: | 3mm/5mm/9mm/16mm |

| Mixing power: | 1.1KW |

| Drum capacity: | 42Lt/30Kg |

| Net weight: | 138Kg |

| Gross weight: | 200Kg |

| Dimensions: | 801x706x1210mm |

III. Safety Instructions

- Please read the operation manual carefully before assembling and testing the machine, and strictly abide by the standards.

- Please inform the professional service engineer in time when the safety or protection device has problems.

- Do not replace spare parts without authorization.

- Comply with cleaning and maintenance rules.

IV. Security Parameters

1. Overview:

- Switch

- Unger system

- Blockade

- Mixing system

V. Description of Operation

1. Principle of operation

The agitator is driven by a reducer and motor. It can be used to process pork, beef, fatty meat, mixed meats, fish and lamb.

2. Switch operation

The machine is turned on by pressing the push button switch. The switch is only used to turn the machine on and off.

VI. Operation Manual

1. Installation

Unplug the machine when installing replacement parts.

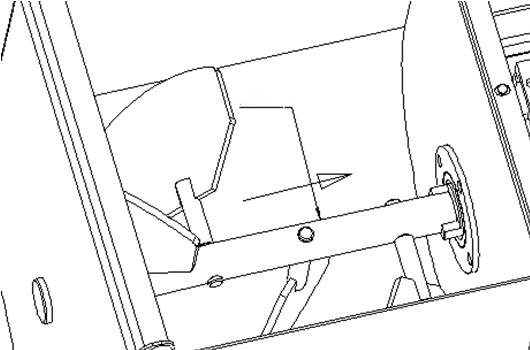

1.1 Agitator

First pre-install the agitator, adjust the position of the agitator, then close the front cover, and finally secure the closure.

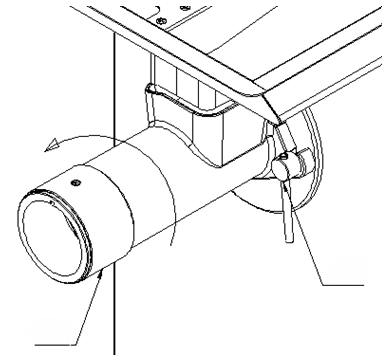

1.2 Grinding mouth

First pre-install the handle, do not tighten it, then install the grinding mouth, adjust the position of the grinding mouth (the entrance of the grinding mouth should be vertical), and finally tighten the handle.

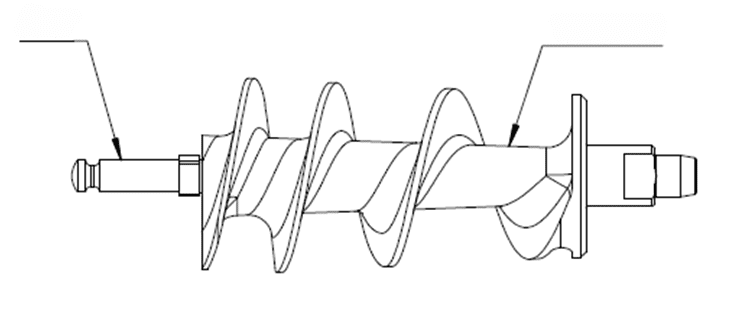

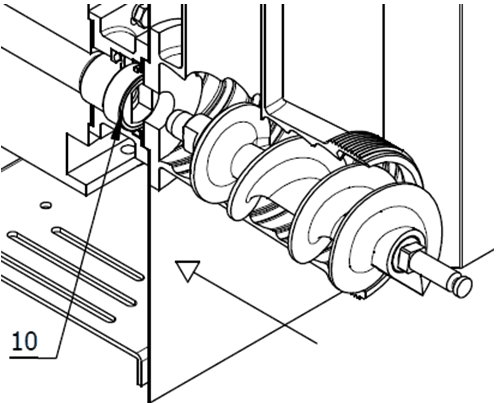

1.3 Archimedes screw

Install the Archimedes screw into the grinding mouth and insert the screw into the shaft (10).

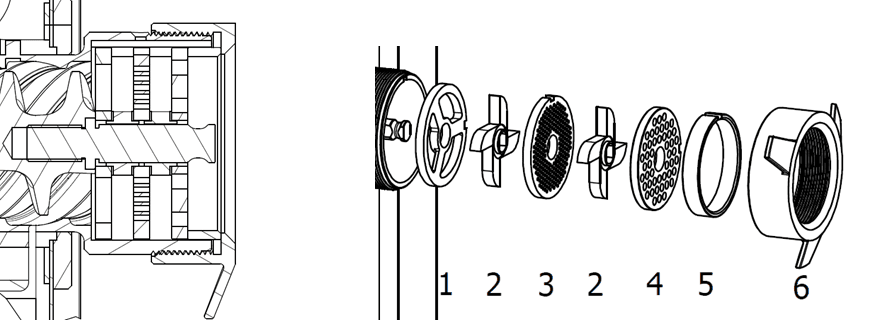

1.4 Unger System

The Unger system includes Perforated Plate (1,3,4), Cutting Blade (2), Spacer (5) and Locking Wheel (6).

Attention:

- The cutting blade works in counterclockwise rotation, and please pay attention to the assembly steps.

- Unplug the machine when installing the cutting blade system.

2. Disassembly

The reverse procedure to the installation procedure (VI. 1).

3. On and off

The machine starts working and is switched off by pressing the button switch.

4. Installation

4.1 Location

Sufficient space for operation and cleaning is required before installation.

4.2 Connecting electrical devices

- The voltage supply must match the label.

- It is necessary for an electrical engineer to connect the main power.

- Connect the power supply when the machine is operating.

- The machine is only for mincing and mixing meat.

4.3 Rotation test

A short power supply connection is required before working, do not install the spare parts and cutting blade, make sure the rotation direction is correct. The rotation direction should be counterclockwise when we look at the Archimedes screw, or adjust the power connection.

VII. Problem analysis

| Problem | Reason | Solution |

|---|---|---|

| The machine does not work when turned on | No connection to the power grid | Connect the power supply |

| Power outage | Check the fuse and circuit | |

| Foreign matter in the grinding mouth | Clean the foreign matter | |

| The engine runs abnormally or overheats | Overload operation | Clean cartilage, tendons and large pieces of meat |

| Voltage too low | Check the circuit |

Attention: Unplug the machine when checking and cleaning.

VIII. Cleaning

Attention:

- Carefully protect the spare parts when disassembling them for cleaning.

- The machine, electrical equipment and components on the machine board must never be washed using water, or in any form of jets and quantities; therefore, no “bucket” or “towel”. Never place the machine directly in the sink or under the tap.

Cleaning the grinding mouth:

Clean the grinding mouth and Archimedes screw every day separately.

Attention: Unplug the machine before cleaning.

IX. Maintenance

1. Electrical equipment:

A complete check of the electrical equipment is required every month.

Technical Support and Warranty

Do you have questions about how to use your meat grinder and mixer to optimize your industrial production? ARC Distribution is here to help you.

Exclusive 2 Year Warranty

All meat mincers and mixers DMX-32A distributed by ARC Distribution They have a Full 2 year warranty covering manufacturing and operating defects, giving you complete peace of mind for your industrial investment.

Technical Service Throughout Europe

ARC Distribution offers specialized technical service in all European countries, guaranteeing close support regardless of your location:

Spain

Portugal

France

Italy

Germany

United Kingdom

Ireland

Belgium

Netherlands

Luxembourg

Denmark

Sweden

Finland

Austria

Greece

Cyprus

Malta

Poland

Czech Republic

Slovakia

Hungary

Slovenia

Croatia

Romania

Bulgaria

Estonia

Latvia

Lithuania

Find Your Nearest Technical Service

To find the service center closest to your establishment, visit our technical service finder by map, where you can easily locate support available in your region.

Full Range of Meat Processing Machinery

The chopper and mixer DMX-32A is part of our wide range of solutions for the meat industry. ARC Distribution offers equipment for all needs:

Meat Mincers

Models of different capacities for all types of meat industries.

Filleting machines

For fresh or frozen meat, with different cutting options.

Dicing Machines

Precise solutions for uniform meat cutting for different applications.

Explore our Full range of industrial meat machinery including meat mincers, slicers for fresh or frozen meat and dicing machines.

For technical support, spare parts inquiries, or industrial application advice, please visit https://distribucionarc.com/producto/picadora-con-mezcladora-de-carne-industrial-1000kg-por-hora/ or contact our team specializing in solutions for the food industry.