“Industrial dicing machine from 5mm to 25mm.” has been added to your cart. View cart

VAR-180 can seamer

3.341,63$ Taxes included

Filtration machine, microfiltration and ultrafiltration of liquids

34.588,75$ Taxes included

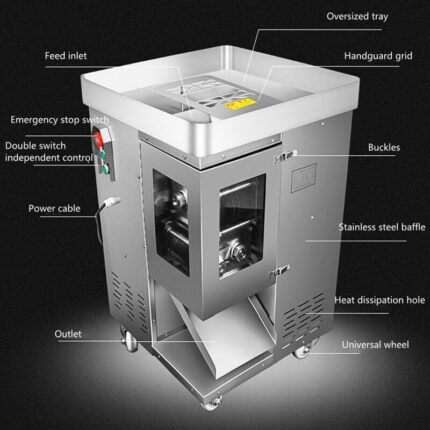

Machine for cutting pork loin or fresh meat into fillets

6.683,25$ Taxes included

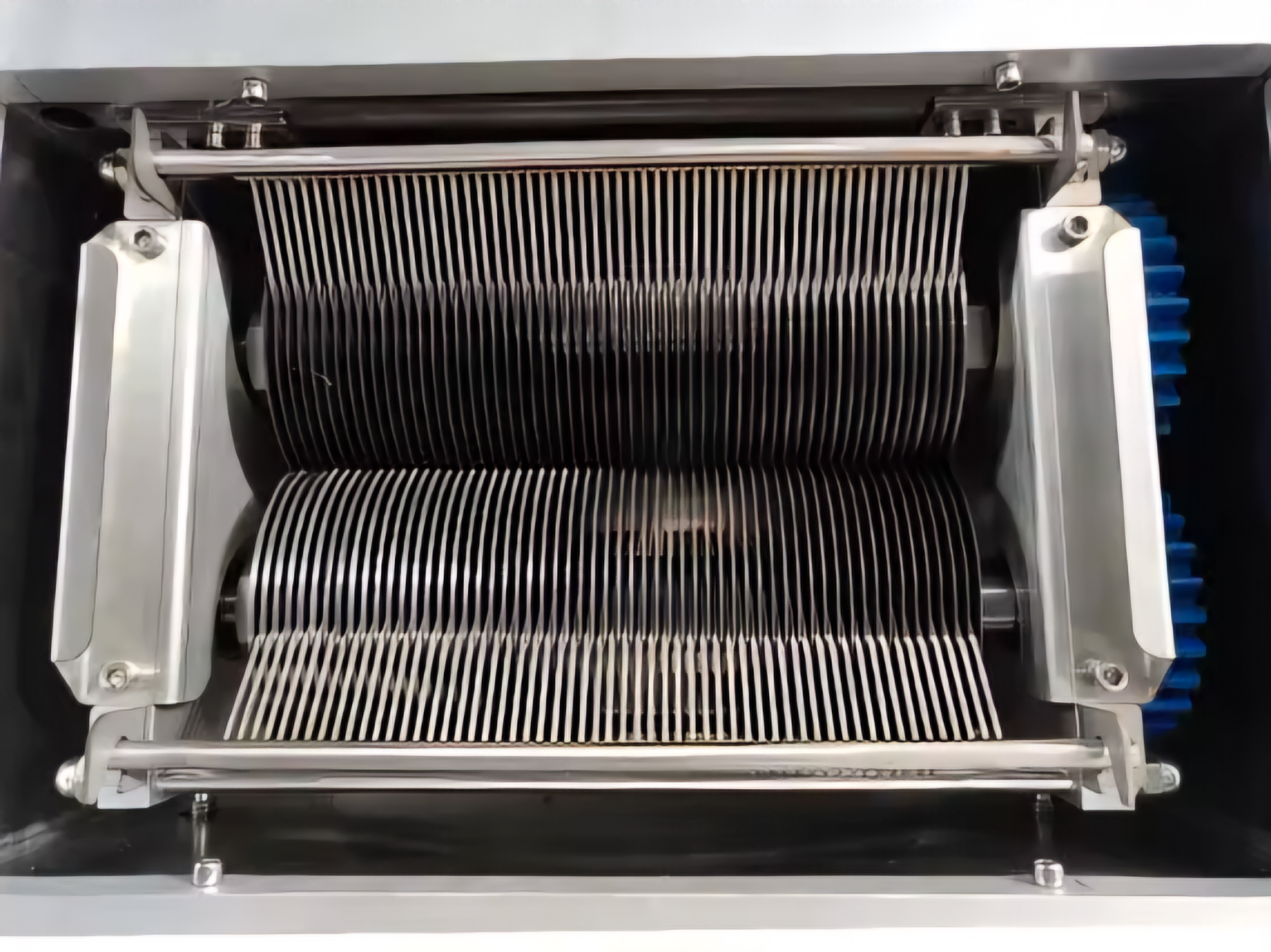

The meat filleting machine is designed to cut fresh meat with precision. Constructed of 304 stainless steel to resist moisture and corrosive agents, it features wheels for easy transport and interchangeable blades for different cutting thicknesses, prioritizing operator safety.

Discover our fresh meat cutting machine with an entry of 250 mm long by 100 mm wide, designed to work with meat boneless. Ideal for butcher shops, restaurants and food processorsThis machine offers uniform and high-precision cuts for the following types of meat and preparations:

SKU:

AR10156

Categories: Meat slicers, fillets

Description

Boneless fresh pork or beef meat slicer

Our meat slicer fresh for fillets of pork loin The machine is designed to meet the needs of butchers, restaurants and food processors. Thanks to its robust construction, high precision and advanced technology, it allows fresh and boneless meat to be processed quickly and evenly, maximising productivity and reducing waste.

This machine It is specially designed to make fillets of meat fresh, such as: pork loin, peceto, buttock, pork loin, chops, boneless ribs (pig), broad loin (beef), aguyon, entrecote, sirloin and poultry breast without skin or bone.

Find out more details about our warranty here: Warranty Policy

Preventive maintenance optional annual reviews: Preventive maintenance

Machine Technical Specifications Table

| Specification | Detail |

|---|---|

| Power | 2200W |

| Speed | 1400 RPM |

| Voltage | 220V |

| Dimensions | 45 cm x 76 cm x 48 cm |

| Weight | 100 kg (approximately) |

| Cutting speed | 300 to 600 kilos per hour |

| Cutting blades | 2.5mm, 3.5mm, 5mm, 7mm, 10mm, 15mm, 21mm |

| Meat input size | 270mm long x 100mm wide |

| Meat output size | 300mm wide x 200mm high |

| Warranty | 2 years with ARC technical support |

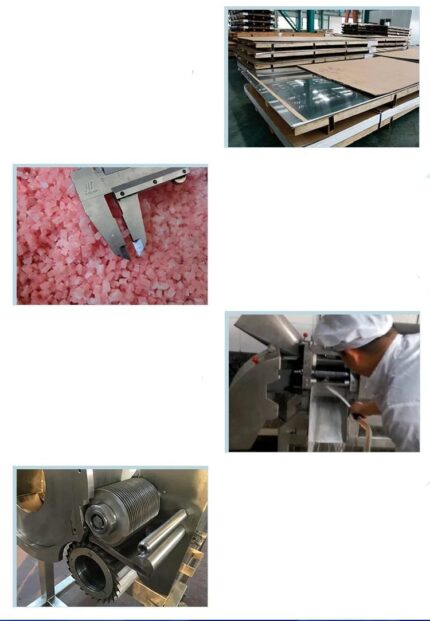

The meat fillet cutting machine It is designed to cut fresh meat. Built entirely from 304 stainless steel to offer better resistance to moisture and possible corrosive agents (such as blood that pieces of meat may have, for example the liver), this machine can also cut this type of fresh meat without any problem.

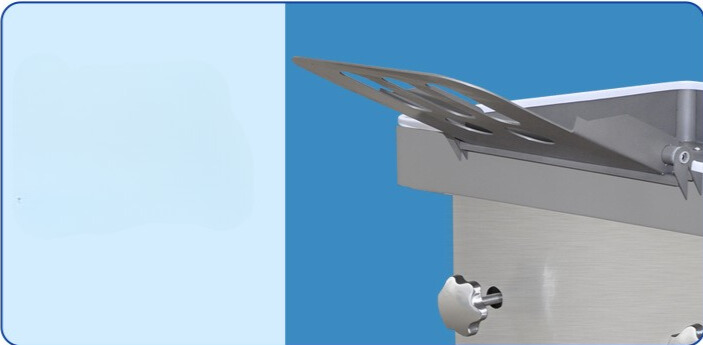

Top of the meat slicer

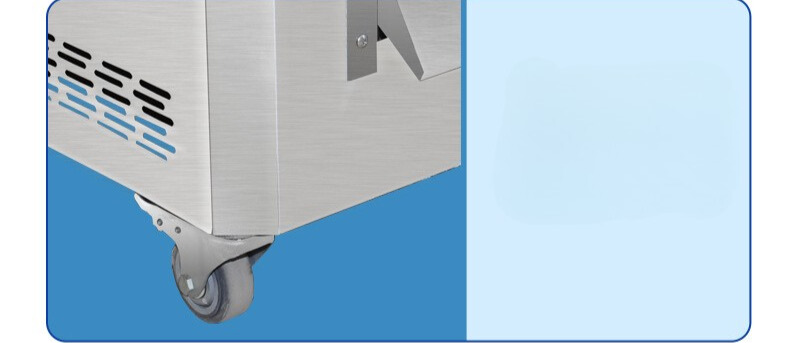

The meat cutting machine also has wheels so that it can be easily stored or moved to the workplace. This machine is ideal for butcher shops where space is limited and a very practical option is these compact machines.

Wheels on the bottom for easy transport

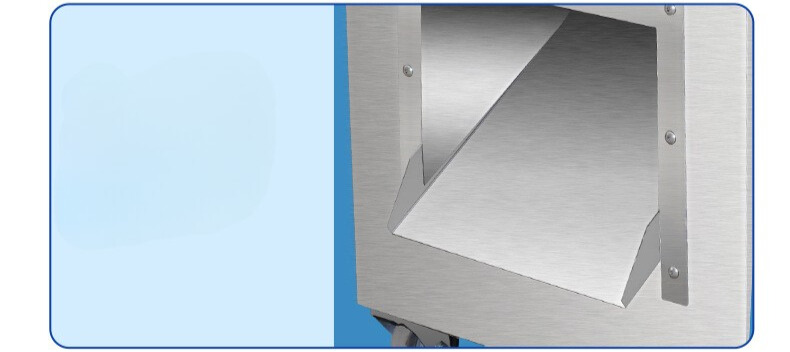

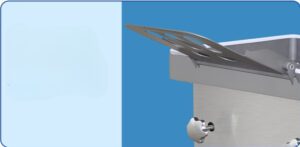

The machine's outlet, after cutting the meat, has a 95-degree inclination so that the fillets slide smoothly while being cut and fall into the indicated container.

Departure after cutting the fillets

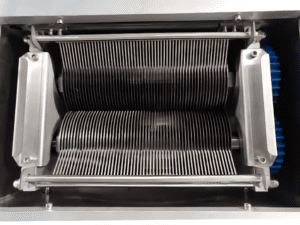

Below we will explain everything related to the blades of the meat slicer and how to change the blades. In the case of this machine for cutting fresh meat into fillets, it is necessary to change the blades depending on the desired thickness of the cut. For example, you buy the machine and it comes with a set of blades to cut chicken breast at 5 mm, but then you need to cut beef tenderloin at 20 mm; in that case, you have to purchase another additional set of blades.

Why can't the thickness be adjusted directly on this machine? The answer is simple: for safety reasons. If the blade part were adjustable, it could be very dangerous for the personnel operating the machine. That's why it's better to have fixed blades. In conclusion, if you have different types of cutting, it's necessary to buy as many blades as necessary.

In the picture you can clearly see: first disconnect the machine from the power supply, then remove the two screws on the front. Once the safety is released, lift the top cover and you can access the blade compartment, remove the blades and replace them with the ones you are going to use (or simply to clean the machine). To reassemble the blades, just follow the same steps in reverse.

How to Change the Blades of the Machine for Different Cuts

We also have custom made blades for the meat cutting machine but we also have custom and standard ones. The blades have cleaners between the cutting blades so that they do not get stuck or leave meat residue and can guide the meat correctly to the cutting blades.

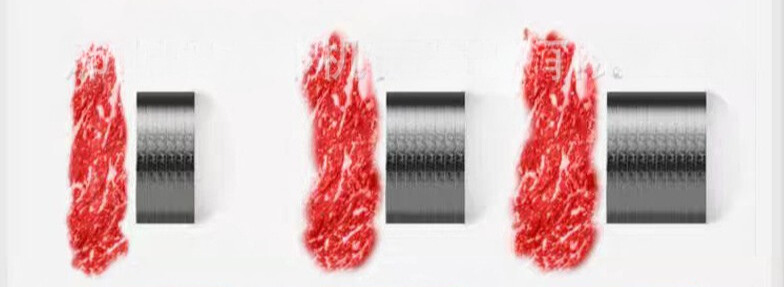

The images show the cuts of meat that the machine can make, with a thickness range from 2.5 mm to 20 mm. This allows it to adapt to the specific needs of each type of meat or preparation.

Table 1: Measurements of the smallest cuts

| 2.5mm | 3.5mm | 5mm | 7mm | 10mm |

Table 2: Measurements of the largest cuts

| 12 mm | 15 mm | 20 mm |

Below I will show you a video that explains why this meat cutting machine Fresh is ideal for butcher shops, restaurants and food processing plantsIt is a true 3 in 1, which means it can perform three types of cutting:

- Steaks: With the first cut of the piece we obtain uniform fillets.

- Strips:If we take those fillets and pass them through the machine again in a horizontal position, we can turn them into strips of meat.

- Dice: Finally, if we take those strips and pass them through the machine again, we get dice. Although the dice will not be perfectly square, they will have a uniform diameter depending on the size of the blades installed. For example, if the blades are 15 mm, the thickness of the fillet, strips and dice will always be 15 mm.

Want to see this machine in action? Click here and don't miss it

In this video you will see our machine in action performing these processes. If you want to optimize cutting times in your butcher shop or business, this machine is the perfect solution to reduce work and improve efficiency. Don't miss it!

Applications and Uses For different types of meat

This machine is versatile and allows for processing different types of fresh boneless meat for a variety of preparations. Some of the most common cuts include:

-

Pork loin steaks

- Part used: Whole or portioned loin.

- Thickness: 5 to 10 mm.

- Application: Tender and lean fillets.

-

Milanese (Argentina)

- Parts used: Thigh, rump, loin ball (beef or veal).

- Thickness: 3 to 8 mm.

- Application: Fine cuts, ideal for breading.

-

Boneless chops

- Parts used: Chops, boneless ribs (pork), tenderloin (beef).

- Thickness: 10 to 15 mm.

- Application: Perfect for grills and stews.

-

Premium Steak Beef

- Parts used: Sirloin, entrecote, tenderloin.

- Thickness: 8 to 20 mm (depending on the cut).

- Application: Steaks for grilling and gourmet dishes.

-

Sliced chicken breast

- Part used: Skinless, boneless breast.

- Thickness: 4 to 8 mm.

- Application: Versatile for quick and healthy meals.

-

Escalopes (veal or beef)

- Parts used: Hip, rump, buttock.

- Thickness: 2 to 5 mm.

- Application: Breaded or quick stews.

-

Lean meat for stir-fry

- Parts used: Black meat, rump, rump cap (beef); breast (chicken).

- Thickness: 3 to 6 mm.

- Application: Light and uniform stir-fries.

-

Vacuum-packed steaks

- Part used: Boneless flank (beef).

- Thickness: 5 to 12 mm.

- Application: Juicy roasts or steaks.

-

Fajitas (beef or chicken)

- Parts used: Skirt, flank (beef); breast (chicken).

- Thickness: 5 to 10 mm.

- Application: Mexican and Tex-Mex dishes.

ARC distribution machines are of European origin, Spain, France, Germany, Italy, Romania, but this is only due to the reduction in manufacturing costs in 304 or 316 steel. Even so, we take care of every detail, especially the quality of the steels used both in the structure and in the cutting blades, which are the most important component. Our blades are manufactured in different types of steel (420, 440 and nitrogen steels) to ensure optimal performance and durability.

Furthermore, compared to conventional Chinese motors, we have selected a specific one with very specific technical characteristics. This choice provides an improvement of up to 300% in performance, reliability and service life, together with high-quality electronic components. For this reason, we offer a 2-year warranty on our meat cutting machines. We recommend reading the terms of the warranty to fully understand our procedures and the commitment we have to each of our customers.

Outstanding Technical Features of the optional structural elements

| Specification | Detail |

|---|---|

| Material | Made of 304 and 316 stainless steel for durability. |

| Cutting Blades | 420, 440 or nitrogen steel, optimized for superior performance. |

| Engine | High efficiency, with an improvement of the 300% compared to conventional motors. |

| Warranty | 2 year warranty, covering key components and labor. |

| Cutting Capacity | Fresh, boneless meat, suitable for various types of cuts. |

Reviews (0)

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.